Use and Misuse in «Avoiding Time Loss»

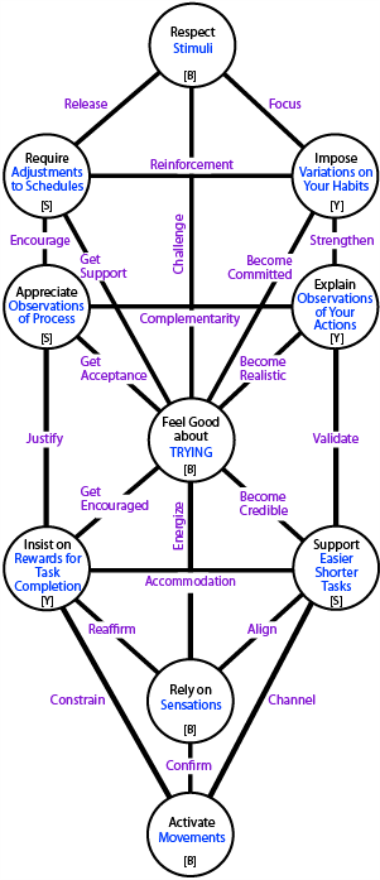

Stop Avoidance to Use Time Well: Framework of all PH-L1s

Introduction

All the emergent frameworks are dynamic states of creative effort. It is conjectured that they are activated naturally in extremis, when the options of exiting or enduring are rejected. This personal choice is an expression of autonomy and transcendence.

However, these socio-mental options have been observed by others with a strong interest in specific goals. That interest more commonly serves money or power rather than the good of each and all. But not necessarily. Applying a framework in this way is always an imposition on another.

Judgement as to whether this constitutes a use or a misuse of human creative potential will vary. If the user is depersonalized or driven by some inner demon, use may tip into abuse. Each framework is examined from this perspective and the findings are compared and reviewed here.

Assembly Lines

Time is money. So is performance. A framework that stops avoidance and ensures performance naturally attracts businessmen employing large numbers. They then force work and people into a system that constructed via PH-L1 Centres: the assembly line. These notes draw on the account in Wikipedia![]() .

.

Factories need to integrate manpower, materials and machines. Before the 20th century, manufacturing usually involved hand-crafting, although the efficiency of assembly by division of labor had been known since the Chinese and Persians used it over two millennia ago. Adam Smith wrote about it in 1776. Marc Brunel (father of the famous Isambard Brunel) used this method with great success in factories constructed for the British Navy in 1801-03.

The most famous and globally influential development was in the Ford Motor Company. Henry Ford wanted to produce a cheap, reliable car for middle-class America. He realized that by arranging the layout of the factory he could reduce the time-wasted in worker movements. He arranged for assembly to occur in sequence with minimum movement of workers as well as automated and minimum movement of parts. Workers typically performed just one operation repetitively.

Ford's system allowed employment for almost anyone, reduced worker injury, paid high wages and reduced the working week—as well as producing ultra-cheap cars. It's success is undoubted.

Using the PH-L1 Framework

. Stimuli for work-action are provided by the assembly process. These must be responded to without fail or the whole line breaks down and the entire output is disrupted. Social interaction is limited or prohibited to ensure no distractions.

. Natural worker habits are stopped. New strictly enforced habits that are specifically adapted to the machines and products are imposed. Schedules and timing of repetitive actions are adjusted to the nature of the assembling process.

. Careful observation of the assembly process and the actions that workers need to take are explained in terms of goals and possibilities, which then leads to improved efficiency.

. Company managers keep looking for blockages and time-wasting. Time-and-motion studies suggest time-economies and ways to improve efficiency. Study of physical ergonomics helps because musculo-skeletal disorders are prevalent in repetitive activity leading to disruptive dysfunction and absenteeism.

. Tasks are made much shorter and easier, often ultra-simple and ultra-short with almost no thinking required. Ford provided worker rewards, but that has not always been the case.

. Sensations, usually visual, but also auditory and tactile, provide essential feedback for task initiation, performance and completionwithout error or injury. Attention and awareness must be focused but thinking is not required.

. Assembly line work relies on the worker making simple movements, and ensures removal of unnecessary physical movement, especially walking about, by using conveyor belts.

Experience of Being Forced

In the framework of PH-L1s, a person is an instrument, but chooses that autonomously. However, in this use, there is no autonomous personal determination to «overcome failure» that is intrinsic to the original conception.

Many have noticed that employers are often not as considerate as Henry Ford. They pay low wages, restrict space excessively, ignore noise issues, neglect ergonomic factors and make their staff ill. Foxconn, a firm that manufactures for Apple, Sony, Nintendo, HP and others in China, has a history of suicides including one occasion when about 150 workers threatened mass suicide: see CBS Report![]() and Telegraph report

and Telegraph report![]() .

.

But even in the optimum scenario, there is something mind-numbing about the demands of assembly line work. Ford discovered just how distasteful most found it: “every time the company wanted to add 100 men to its factory personnel, it was necessary to hire 963”.

Initially posted: 20-Sep-2013. Last updated: 18-Jan-2015.